Supply Chain Management

Sustainable value creation systems through the use of integrated IT systems

Supply chain management is concerned with the holistic design, coordination and control of material, information and financial flows within and between companies. The aim is to increase efficiency and sustainability in value networks. This is achieved by digitally connecting companies and using innovative technologies. These increase transparency, improve corporate performance and promote sustainable business practices.

Digital networking and cooperation between companies

The team Supply Chain Management (SCM) creates sustainable value networks by using integrated IT systems. Our goal is to holistically design and coordinate cross-company value-added processes – from the supplier to the end customer and back. We place particular emphasis on supporting manufacturing companies on their way to circular and sustainable value creation. In doing so, we not only take environmental and social aspects into account, but also combine these with an increase in economic efficiency and competitiveness.

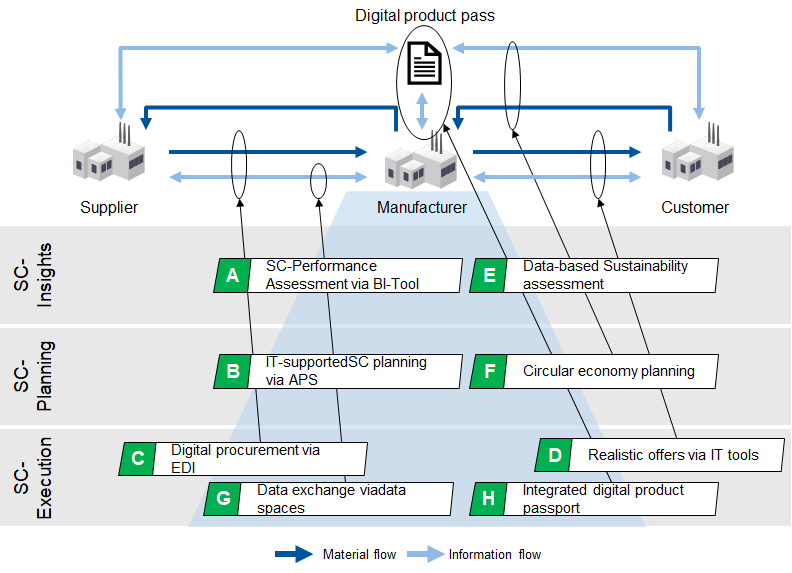

We focus on the digital networking of companies to increase their transparency, resilience and sustainability. We analyze the influence of innovative technologies on the supply chain (SC) in order to design efficient and sustainable processes. Our work is based on three central levels: SC-Insights, SC-Planning and SC-Execution.

SC-Insights: Transparency of current value-adding activities

With the help of business intelligence tools and sustainability software, we measure the performance of the supply chain and carry out data-based sustainability assessments. The intelligent integration of systems and the development of standardized information flows helps to avoid data silos and enables efficient, comprehensive evaluations, including the derivation of measures. On this basis, companies are given the opportunity to make well-founded decisions and design their value chains more efficiently. A high degree of transparency helps to identify weak points at an early stage and to take targeted optimization measures.

SC Planning: Planning complex value-adding activities

Technical solutions such as APS systems support IT-based supply chain planning and enable the transformation to a holistic, optimized supply chain. Taking into account cross-company dependencies and their interactions, we support the coordination between procurement, production and sales activities in SC planning and thus increase the company's overall performance. Another focus is on planning for the circular economy and overcoming the logistical challenges it presents. By integrating usage data into the planning of supply chain activities, it will be possible in the future to better anticipate uncertainties such as product returns, paving the way for a competitive circular economy.

SC Execution: Efficient and effective implementation of cross-company processes

We optimize collaboration between suppliers and producers through digital procurement processes. This involves the use of data transmission technologies such as EDI or Data Spaces, as well as online shops such as procurement platforms. On the customer side, we improve the quotation process by using specialized IT tools that calculate possible delivery dates based on data (available-to-promise and capable-to-promise functionalities). For confident and integrated data exchange, we are pursuing the possible applications of data spaces and the integration of the digital product passport into the IT system landscape in the production environment. Specifically, with regard to the digital product passport, we are working on industry-ready solutions to automate and standardize its use and to make it usable as a central data platform for the circular economy.

Our specialist group is driving forward the digital, sustainable transformation of supply chain management in a targeted manner. We support companies in increasing their efficiency, transparency and sustainability. Through our industry-oriented research and the knowledge gained from numerous successful projects, we develop innovative solutions for sustainable, circular and competitive supply chain management.

Contactperson

Further Information

Whitepaper [German]

“Digital vernetzte Supply-Chains brauchen mehr als IT”

“Potenziale der Digitalisierung der Supply-Chain”

Position paper [German]

Publications [German]

UdZPraxis-Artikel: “Von den Besten lernen: Konsortialbenchmarking erlaubt einen Blick auf die zukunftsfähigsten Supply-Chains Deutschlands”

IT&Production-Artikel: “Kooperieren ist nur der Anfang”

UdZPraxis-Artikel: “Risikominimierung in Supply-Chains – Mit einem ganzheitlichen Risikomanagement Lieferketten stabilisieren”

UdZPraxis-Artikel: “Optimale Gestaltung von Supply-Chains – Durch szenariobasierte Analysen eine fundierte Entscheidungsgrundlage schaffen”