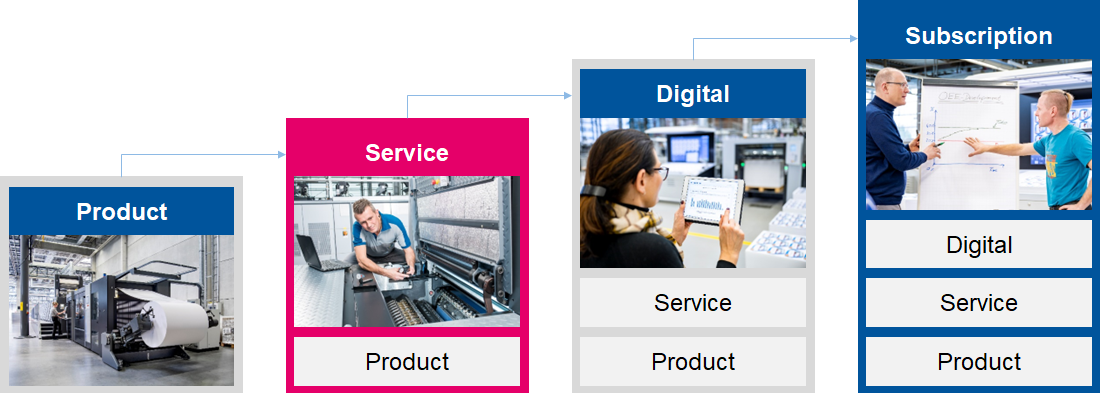

Service Excellence

Developing Maintenance into a Value Driver in the Company

As a service management group, Service Excellence supports manufacturing companies in increasing their competitiveness through an inspiring service business, thereby laying the foundation for a successful service transformation.

The group is dedicated to the study and development of strategies, methodologies and best practices to drive service excellence in organizations and enhance the customer experience to the highest level. In doing so, the group's main objective is to identify practical approaches that enable sustainable improvement in service quality and delivery, and thereby customer loyalty.

Contactperson

Further Information

Research projects (selection):

DM4AR

Datamanagement for Augmented Reality

ReStroK

Reduction of electricity generation costs using historical and current operating and service data of onshore wind turbines

SmartMaintenance

Integrative software solution for an intelligent, demand-oriented maintenance management in complex production surroundings

Downloads:

Whitepaper “Smart Maintenance”

Smart Maintenance – just do it!

Whitepaper “Return on Maintenance”

A paradigm shift in maintenance services due to Industrie 4.0